09 Jun April 2017 Newsletter

This year continues to start out strong for construction. There have been a few blips in some markets but, as a whole, the Southeast continues to be the strongest market for construction in the country. The strength of the construction economy has resulted in quite a few price increases this year but the good news is that the price increases abated a bit recently. See below for a detailed look at pricing trends for the major products we distribute.

Dear Friends:

This year continues to start out strong for construction. There have been a few blips in some markets but, as a whole, the Southeast continues to be the strongest market for construction in the country. The strength of the construction economy has resulted in quite a few price increases this year but the good news is that the price increases abated a bit recently. See below for a detailed look at pricing trends for the major products we distribute.

-

- Unlike every other month in 2017, few of the manufacturers of products we distribute increased prices or announced price increases in April. There were a few exceptions which are mostly related to steel construction products.

-

- Both Hohmann & Barnard and Wire Bond, the two largest manufacturers of masonry reinforcing and ties in the eastern US, announced they will increase prices on May 1st on masonry reinforcing and all wire rod masonry accessory items. The amount of the increase will be between 12 and 13%. All orders placed with Hohmann & Barnard before May 1stmust ship by May 19th to be billed at current prices. All orders placed with Wire Bond prior to May 1st must be shipped by May 26th to be billed at current prices. If you have any projects that require masonry reinforcing or wire rod masonry accessory items we strongly urge you to place your orders prior to May 1st.

-

- Concrete wire mesh reinforcing mills in the eastern US either increased prices in April or will increase prices by May 1st by 7%. Higher costs for wire rod was cited by all as being the reason for the price increase. If you are bidding projects which require concrete reinforcing wire mesh, please be sure to get a quote from your New South Construction Supply sales representative.

-

- Polyethylene resin manufacturers were unable to push through the April price increase; therefore, polyethylene sheeting manufacturers will not increase prices in early May as they had previously indicated. Resin manufacturers will try to get a $.05/LB price increase for May orders and if they are successful expect polyethylene sheeting manufacturers to increase prices by June 1st.

-

- Scrap steel posted down by $15/ton on US metal exchanges in early April and most analysts expect no change in the price for May. As the cost of scrap steel is not predicted to increase in May, domestic rebar mills have indicated there prices will unchanged in May from April.

-

- Imported rebar offerings for June/July delivery were unchanged in April from March , but are still 12 to 13% higher than offerings for April/May delivery. Most analyst expect offerings for June/July delivery to remain the same until the International Trade commission makes its final rulings on anti-dumping duties on July 6th (Turkey and Japan) and August 28th (Taiwan).

-

- Prices for southern yellow pine dimensional lumber have risen steadily since March and are expected to continue to increase into May due to high demand. Most analysts predict prices will increase between 3 and 5% in May depending on the grade and size. If you have projects which require these products, we strongly urge you to buy them out as soon as possible to avoid paying higher prices in the weeks to come.

-

- The producer price index (PPI) for final demand in March, not seasonally adjusted, increased 0.2% from February and 2.3% year-over-year (y/y) from March 2016, the Bureau of Labor Statistics (BLS) reported on April 13. AGC posted tables and an explanation focusing on construction prices and costs.

Click here for the latest update on the construction economy from Ken Simonson, the chief economist of the AGC.

Wire Bond

Innovation in Masonry Construction

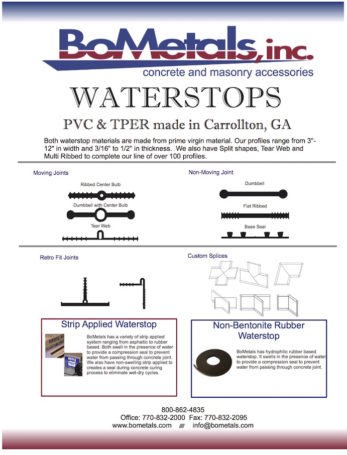

BoMetals

A Leader in Concrete and Masonry Accessories

Simpson Strong-Tie

Connecting Systems for Wood, Steel, Masonry, and Concrete

Brendon Wilson

Our associate profile this month is of Brendon Wilson an inside salesperson at our Hardeeville (Hilton Head/Savannah) branch. Brandon was born in San Mateo, California and graduated from Knoch High School in Saxonburg, Pennsylvania. Right out of high school he joined the United States Marine Corps where he served for four years before joining us in April of 2015. He initially started with us as a rebar fabricator and was promoted to warehouse manager before moving into inside sales. Brandon has two children so his main hobby is spending time with his family and he also likes fishing and watching Steelers, Penguins, and Pirate games. Brandon’s versatility has been a great addition to our Hardeeville team and we are lucky to have him.

Our management article this month is titled, “Strike a Balance in Your Communication”. The author makes the point that striking the right balance in communicating with those who report to you is more difficult than it seems. It as is easy to over communicate as it is to under communicate. This article should give you some help in finding the right balance when it comes to communicating with those on your team.

APRIL’S MANAGEMENT ARTICLE

Strike a Balance in Your Communication

By James Rampton

There’s definitely some truth in the wisdom that it’s better to overcommunicate than undercommunicate. Ideally, every manager gives their team members just enough direction to get on course and the leeway to do their thing free of micromanagement.

The reality is often different, though. No good boss wants to leave their teams feeling empty-handed or unsupported, so they sometimes veer off too far in the opposite direction. I’ve learned the hard way that overcommunication is easier to fall into than you might think, and it winds up obfuscating my message and wasting everyone’s time.

Fortunately, I’ve managed to get better at figuring out when my communication is more distracting than useful. Here are some of the key criteria I use in order to tell whether I’m overcommunicating.

1. Timing

Timing my message is one of the most important things I’ve learned to do. Determining the urgency of your message and the medium for it isn’t easy, but a good first step is simply being deliberate about it.

For example, when I needed to let my employees know about an emergency, there’s no “wrong” time to send out a mass text message or phone recording (this tool can help).

Email, on the other hand, is more often a check-when-you-can medium, so it’s arguably the least disruptive. But texts, phone calls, and group chat messages on platforms like Slack or HipChat usually draw someone’s attention away from something else. So before you send it, ask yourself whether that’s essential.

2. Redundancy

By some estimates, around 205 billion emails get sent every day. How many of them repeat the same message, perhaps just reworded or with a greater sense of urgency? If an employee doesn’t fully understand the scope of a new project, it might make sense to redefine that scope in new terms—otherwise, you’re just wasting time.

Instead, ask yourself if the message you’re about to send will require additional clarification—but also whether you’ve covered its main point already.

3. Persistence

There’s some evidence to suggest there’s an upper limit to the number of emails an employee can reasonably handle in a day. Some estimate that after more than 50 emails, most people struggle to keep up.

I’ve found that I really need to ponder just how much the messages matter. Sometimes, employees have forgotten about certain tasks or neglected things on a deadline, so I know that persistence in these cases is beneficial. The axiom “trust but verify” applies here. I try to keep those follow-ups to a minimum and only trade notes when there’s new information.

4. Value

There are a number of ways to define “value” when it comes to how you communicate. For example, your message could be valuable because it gives new instructions or because it acknowledges receipt of a different message; the latter isn’t necessarily frivolous. Before I send anything, I ask myself:

- Is this person going to be grateful to have this information?

- What’s the worst that happens if I don’t send this message?

Plus, over time, my team members have learned that I only communicate when I really need to. So they pay more attention when I do.

5. Coherence

An incoherent email—no less than an incoherent pep talk during a meeting—is like a puzzle that people have to solve before they can take any significant action or walk away with new knowledge.

No matter how quickly I need to get things done, I often take my time to craft clear messages for the team, including proofreading my emails before sending them. It’s a good step to make sure my messages are being received and digested efficiently. The University of Wisconsin has an excellent guide on writing clearer, more coherent sentences, and Purdue’s online style guide is a great resource that’s helped me be more concise.

This is my checklist when I want to talk to my team about anything noteworthy. As long as my messages are timed properly, original, persistent but not nagging, valuable, and clear, then I know I’ve minimized the risk of overcommunicating to them.

Still, while overcommunication is bad, undercommunicating can be even worse. It’s all about striking a balance, then maintaining it.

That’s it for this month. I know that, like me, you are happy to see price increases slowing down as many of you have had to work under fixed price contracts using materials whose prices have escalated quite a bit from when you signed the contract to do the work. Hopefully we will enjoy a bit of a breather on prices increases for at least the next month or so.

Best regards,

Jim Sobeck

President 864-263-4377

jim.sobeck@newsouthsupply.com

Connect with us: Twitter | YouTube | Facebook | LinkedIn

Author of The Real Business 101: Lessons From the Trenches

Get your copy below.

For Smashwords (eBook version for Kindle, iPad, Nook) click here

For direct link to Amazon site (Kindle and print version) click here

No Comments